We help companies increase their revenues by improving efficiency and machinery productivity by developing customized automation.

Maintaining efficiency, value, and good functioning of a plant is crucial to be competitive. Nonetheless, it helps guarantee safety standards and a pleasant working environment.

We take care of your plant. Evaluating potential revamping of critical machinery with state-of-the-art software and electro-mechanical design.

We are capable of extending the lifecycle of your plant. Guaranteeing concise ROI and a noticeable reduction in cost if compared to a new installation.

Our services can be provided accordingly to your needs: individually, combined, or with the formula “turnkey”.

Activities and Competences

- Consulting;

- Needs analysis;

- Feasibility studies;

- Detail design;

- Testing;

- Installation and Commissioning;

- Production assistance;

- Staff training;

- Service.

Hardware design

- Schemes

- Material bills

- Plant layouts

- Cable bills

- Documentation

Adopted design software: EPLAN

Software design

- Requirements analysis

- Functional software coding

- Controller software coding

- Supervising software coding

Our most recent projects

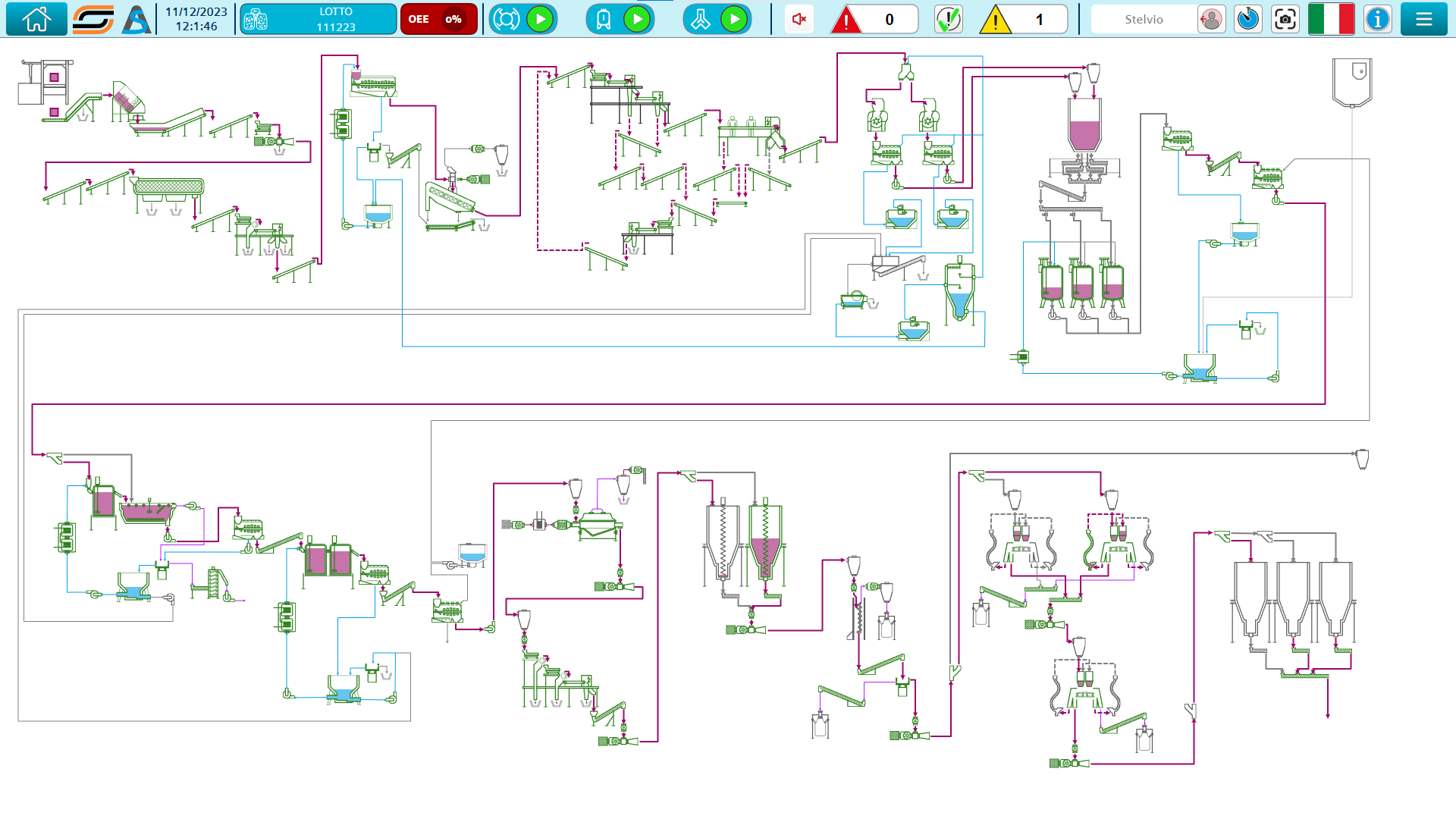

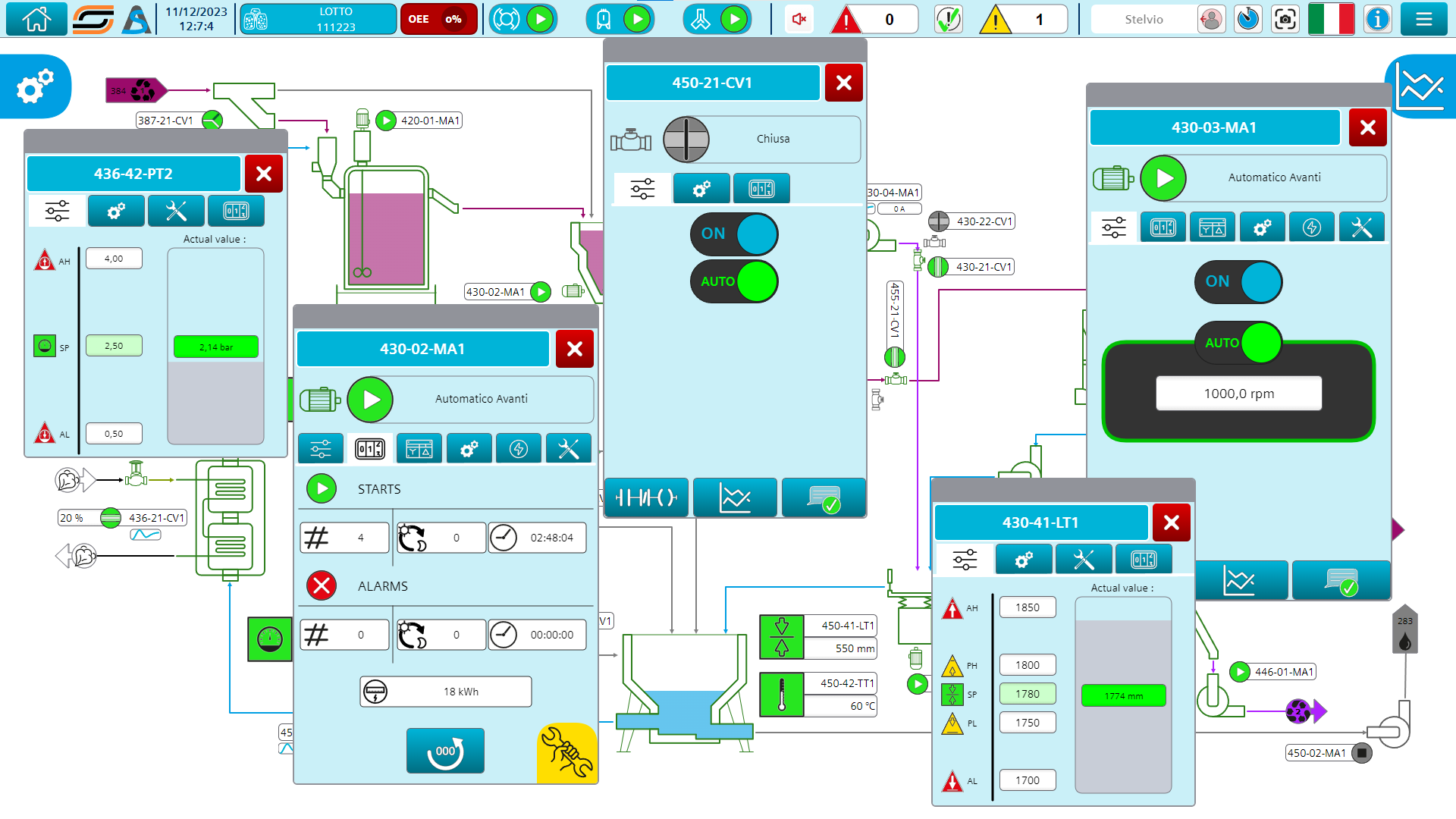

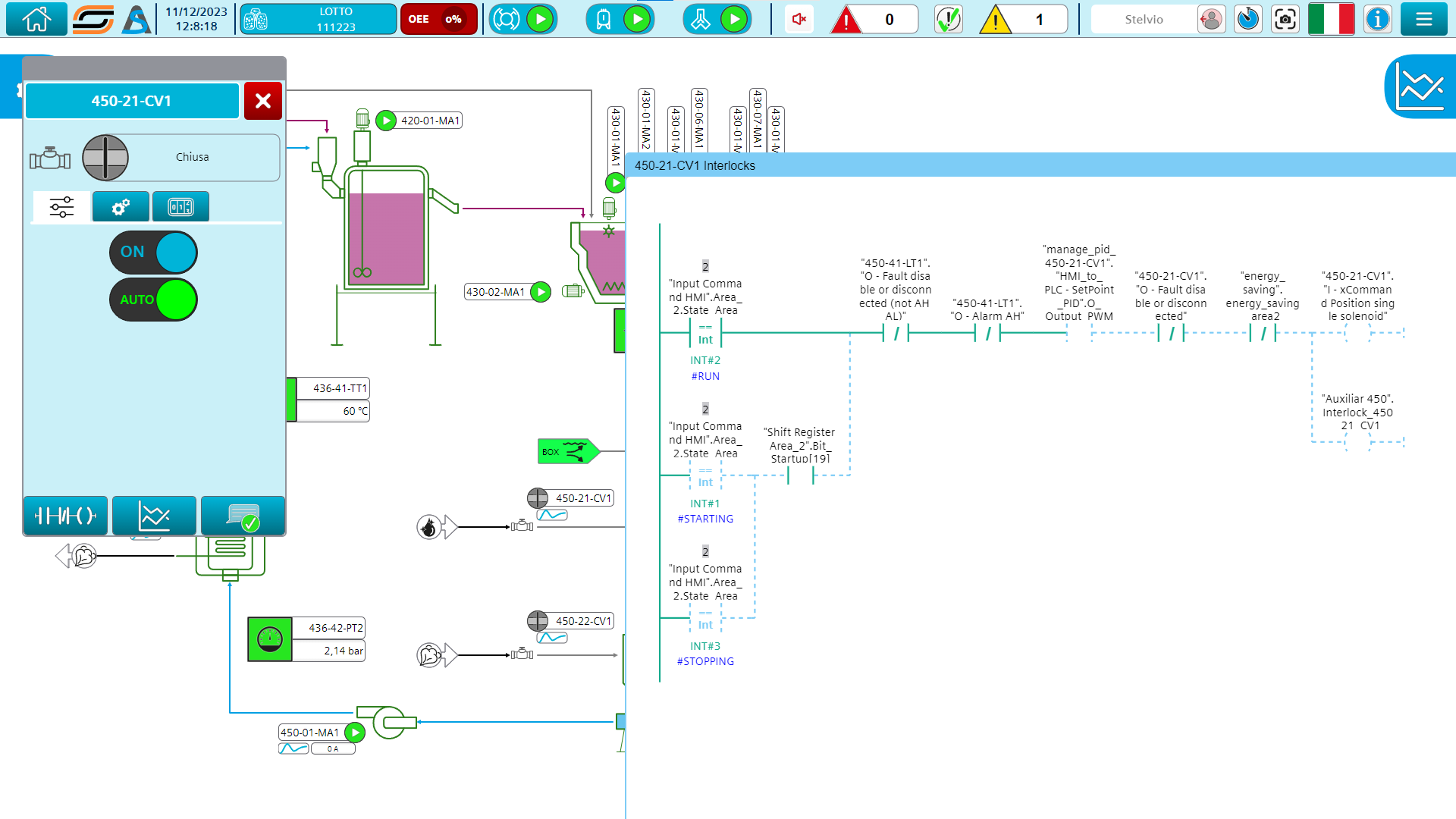

SCADA Project based on WinCC Unified Platform

Modern and innovative SCADA, easy to use.

- Home page depicting the entire plant;

- Communication based on colors and icons.

- Quick and responsive navigation

- Dynamic interface based on active user privileges

- Color customization

- Modular and scalable

- Dynamic fault and malfunction detection assistance

- Prepared for integration into the control room

- Alarms, interlocks, and trends available for each object

- Custom, automatic, and on-demand reports

- Change traceability via AuditTrail

- Recipe management

- Unified and encrypted user management (also with UMCo Active Directory)

- Independent multi-session system

- Encrypted and certified remote assistance connection

- System complies with cybersecurity regulations

Water Treatment Plant for PP Recycling Plant

Development of PLC and SCADA software for chemical-physical-biological water treatment plant for PP recycling plant in the UK

- Treatment of 35 m3/h;

- 24/7 production;

- Siemens Tia Portal v18 PLC;

- Wincc Unified Tia Portal v18 SCADA;

- Remote control via CA certificates;

- Report generation;

- Data & Alarm archiving;

- Profinet connections with assembly line;

- Encrypted PLC SCADA transmissions;

- OPC UA process data exchange.

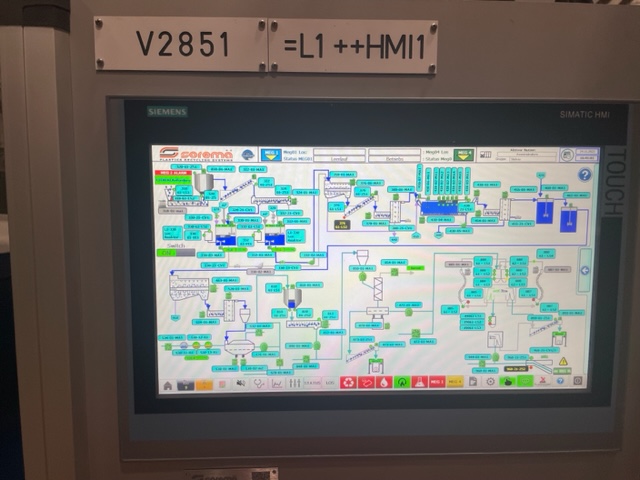

PET processing plant

Automatic PET washing plant with 3000kg/h throughput designrd by Sorema for big German International Company

- 3 distribution cabinet with decentralized peripherals Et200 S;

- 15 Inverters connected in Profinet;

- 2 HMIs with Card Reader Authentication;

- Communication Interface with customer's MES for process data exchange and production data recieving (Lot, ...);

- Connection with upstream and downstream production lines in Profinet PN-Coupler mode;

- Process data archiving

- Production recipes managment;

- Featured with connection for remote assistance.

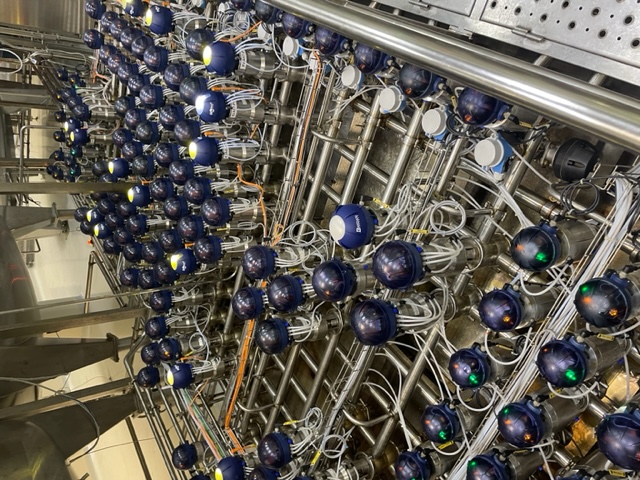

Sistema di trasporto fluidi a matrice

Progetto per trasferimento soluzioni in automatico da Tank di preparazione a linee di riempimento con struttura matriciale, per importante industria Farmaceutica internazionale

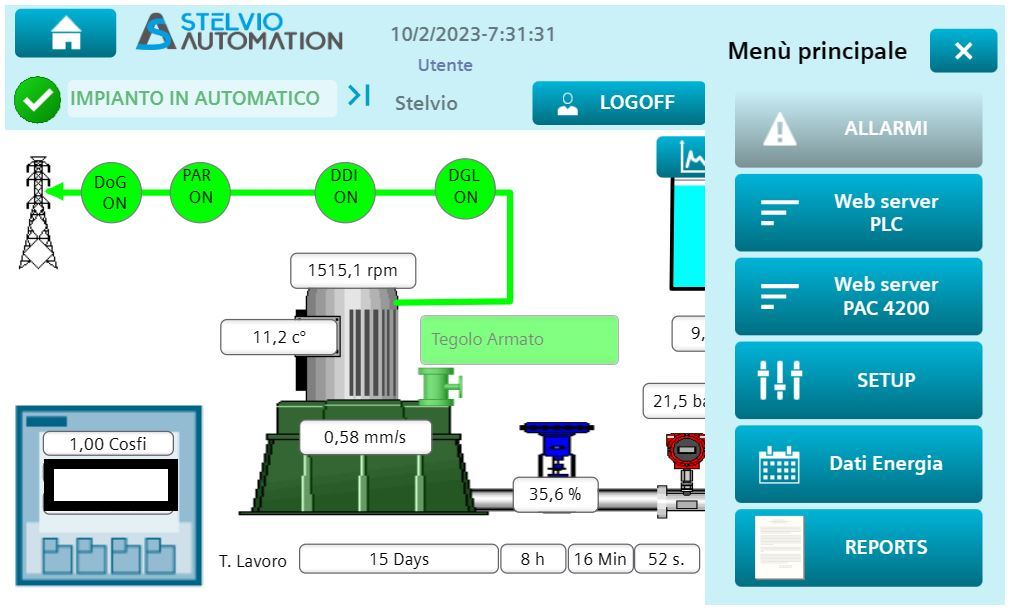

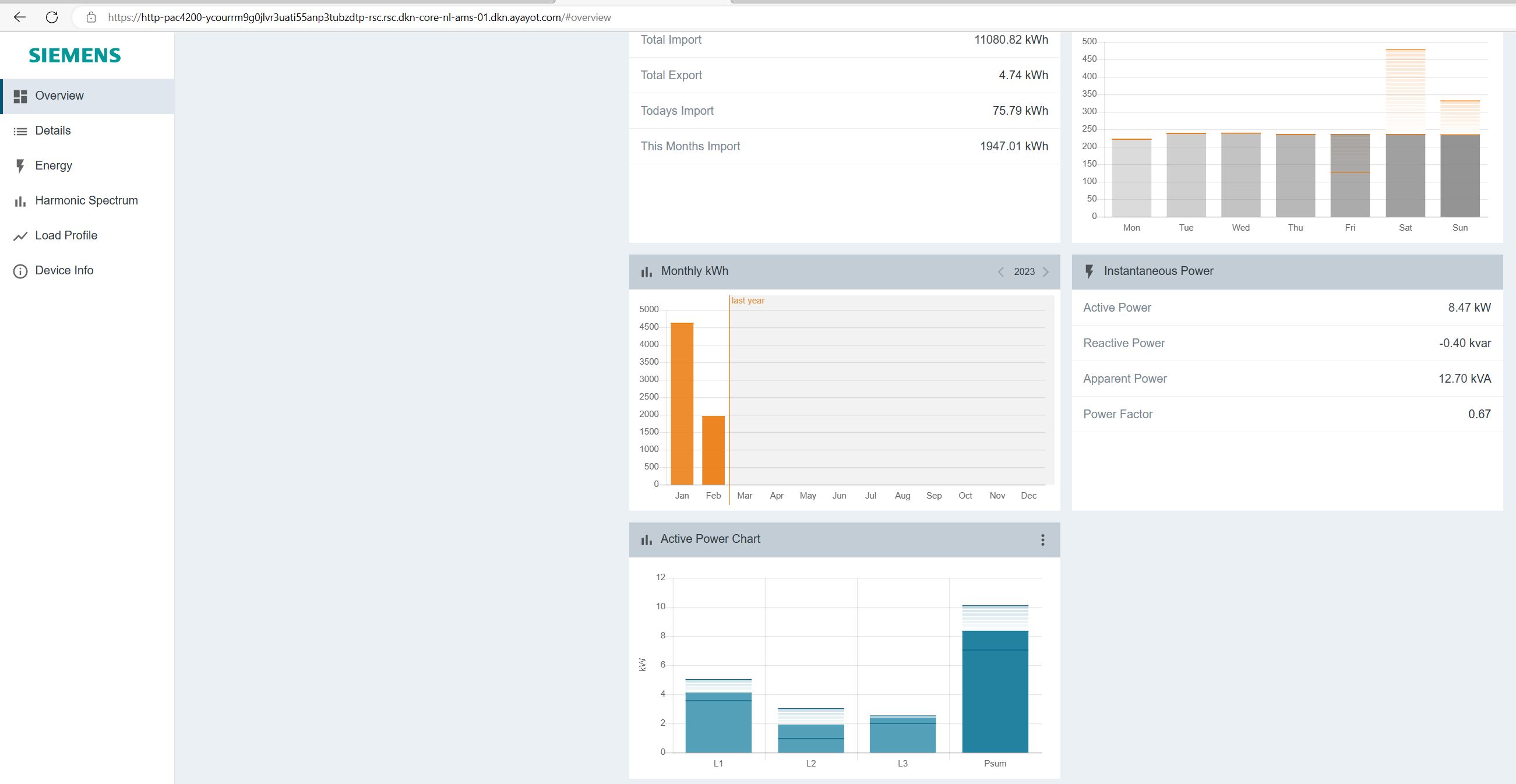

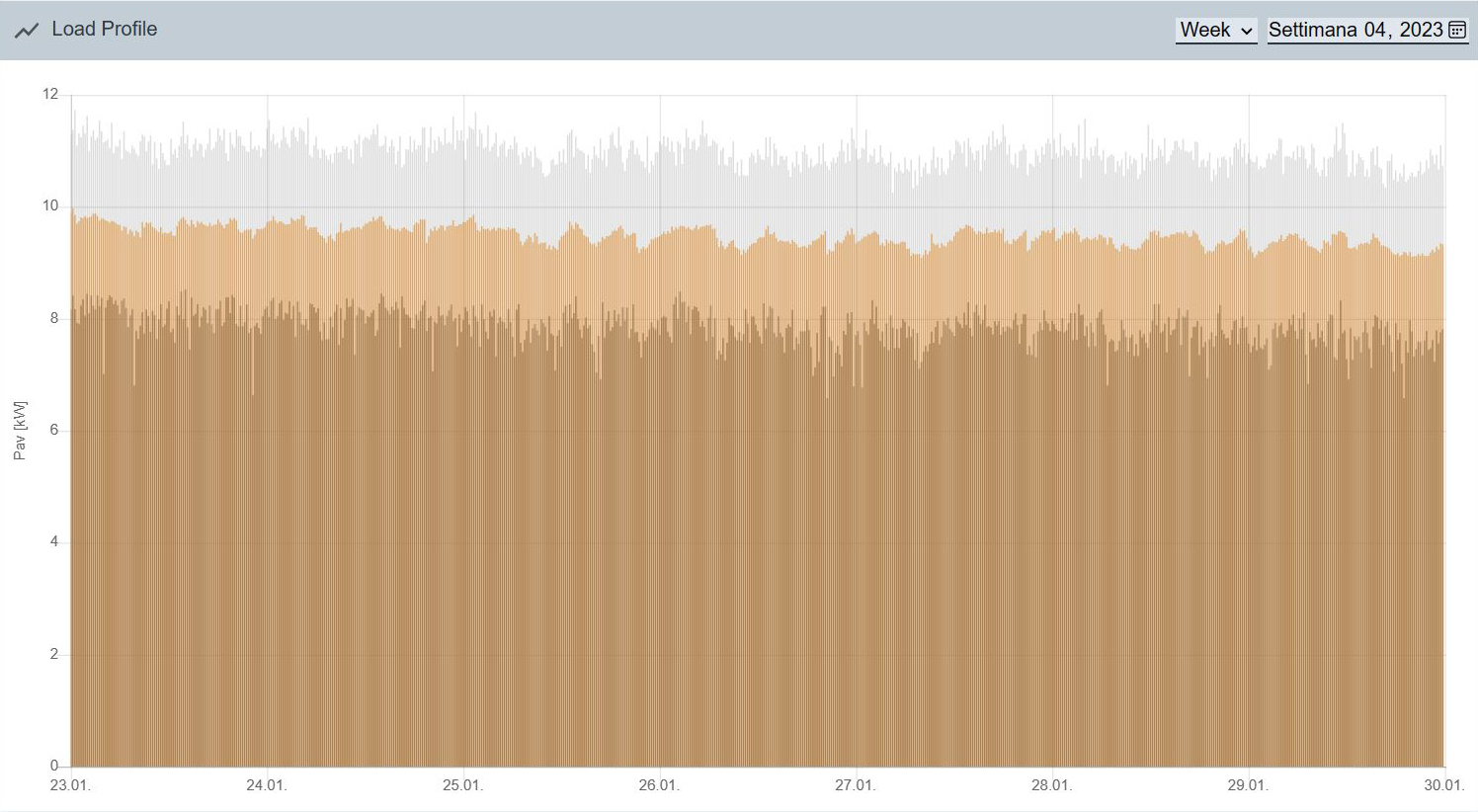

Automated control of a 10kW hydroelectric generator

- Plant

- PLC Siemens S7-1215C;

- Distributed IO ET200sp;

- Fiber Optics connections;

- Power Meter Siemens Pac 4200;

- automatic power factor correction;

- Modbus Tcp/Ip connection between Power Meter & PLC.

- Plant supervisor

- Siemens MTP700 Unified HMI;

- Report generation;

- Data historicization.

- Remoted control

- Remoted HMI-PLC control;

- Automatic alarm sending;

- Web Server PLC & Power Meter.